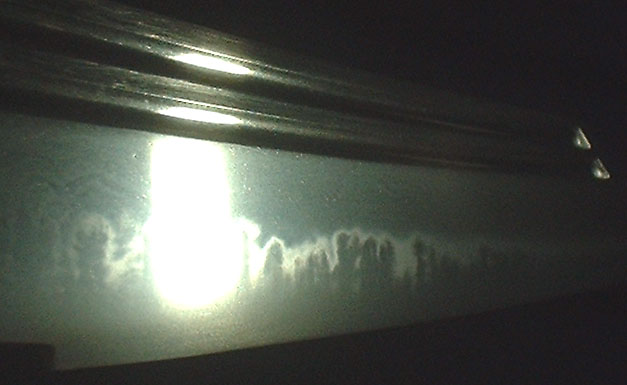

B) Wakizashi in Kissaki-Moroha-zukuri

These blades A and B are made of the same steel in the meaning of before tempering.

The smith forged up one steel block, and then he cut it into two pieces. One was for the blade "A", the other was for the blade "B". The steel construction was Kobuse on the both. The steel blocks were used for the outer steel of each blade. Therefore the two blades were the same steel at the stage before the tempering. So now, we can study how the sister blades have differed through the tempering.

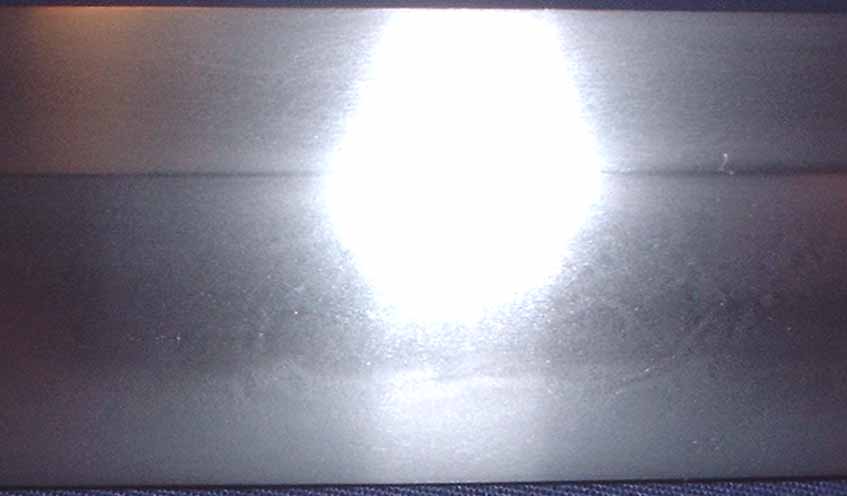

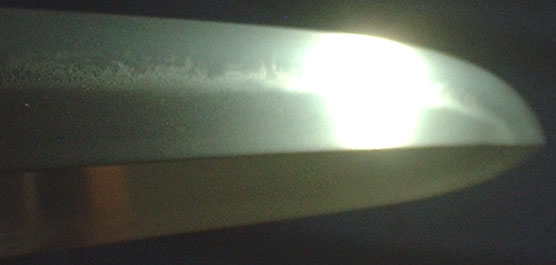

A) Tachi with O-kissaki

blade length 72.2cm, curvature 2.5cm, thickness at the base 8mm, width 3.3cm, weight 930g (Polished by Mr. Tatsuki SUZUKI)

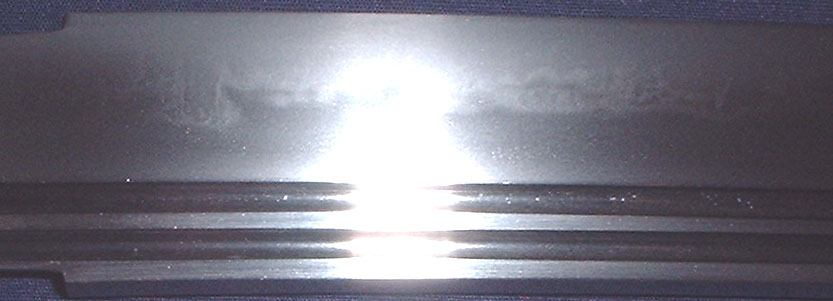

B) Wakizashi in Kissaki-Moroha-zukuri

blade length 31.8cm, curvature 0.3cm (Polished by Mr. Tatsuki SUZUKI)

Now, please compare the two blades polished up.

The layer pattern is the same, large wood grain, on both blades.

The colour of the particles in the ji and in the hamon looks similar. But the shine of them are very different. The shine of the particles in the tachi is mild. That in the wakizashi is strong. It is not a difference of polishing work, because they are polished by the same person who polishes blades very honestly. The polisher said that the wakizashi is harder than the tachi in the stage of finishing.

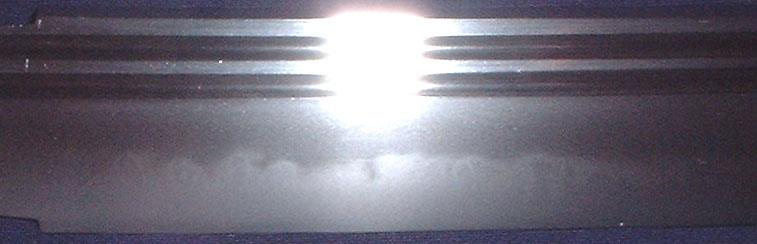

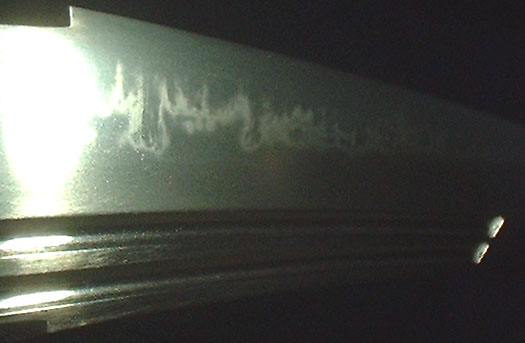

In the blade surface, the large layer pattern is visible on the tachi, but it is not so visible on the wakizashi. The steel particles on the tachi run along the layer. The steel particles on the wakizashi is dense and mask the layer pattern. So the grains of the steel looks different. On the wakizashi, the grain looks compact by full of small chikei.

The hamon on the tachi is made of mild KONIE, including much sunagashi and kinsuji.

The hamon on the wakizashi is also made of KONIE, but include much Nie particles, and the Nie is shining strong. Sunagashi and kinsuji is not as much as the tachi.

The utsuri on the tachi is an active pattern (midare utsuri), and it runs across the steel layer. The appearance is made from the relation between the steel particles and the layer.

The utsuri on the wakizashi is calm, not so active like the tachi.

These are good example to think about the tempering effect onto the steel. The tempering effect makes different appearances onto the same steel.